JCT

JCT

Mar 19,2025

Mar 19,2025

Polyetser polyol mainly play the following roles in the adhesive production process:

1. Base Resin (main component)

As the main component of polyurethane adhesive, it gives adhesive good adhesion, flexibility and chemical resistance.

Affects the curing performance, mechanical strength and weather resistance of adhesive.

2. Toughener

Improve the flexibility and impact resistance of adhesive and prevent the brittle cracking of the bonding layer.

Applicable to high-strength structural adhesives and elastic adhesives, such as shoe glue, woodworking glue, etc.

3. Weathering Enhancer

Improve the UV resistance and chemical corrosion resistance of adhesive, suitable for outdoor or high-performance applications.

Adhesive used in the automotive, construction and aviation industries.

4. Rheology Regulator

Adjust the viscosity, fluidity and construction performance of adhesive to facilitate coating or spraying.

The opening time (operation time) of the adhesive can be adjusted to meet different process requirements.

5. Solvent Resistance Enhancer

Gives adhesive stronger solvent and oil resistance, suitable for high-demand industrial adhesive (such as aviation, electronics and automotive manufacturing).

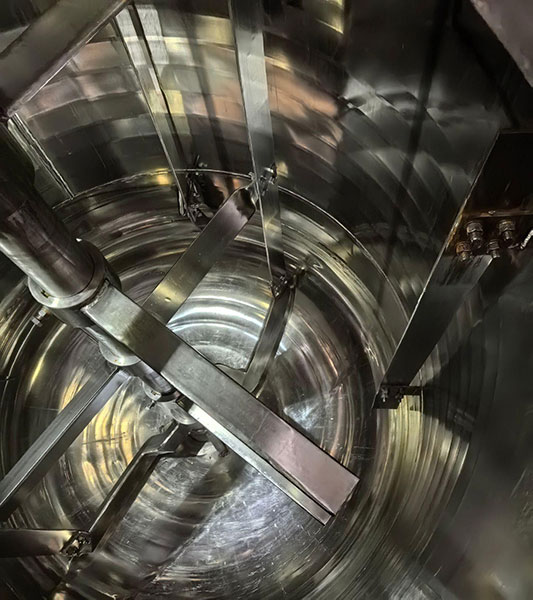

If you want to set up an efficient, stable and automated polyester polyol production line, JCT Machinery provides you witha turnkey project, covering one-stop services such as equipment design, production and manufacturing. installation and commissioning, and technical training.

Just provide your requirements (properties of polyester polyols, annual output, site size, etc.), and JCT will be responsible for everything from solution design to delivery!

Welcome to contact us for customized polyester polyol production line turnkey project: +86-181 3837 3963 or jctben@mixmachinery.com.