Widely Applied and Expanding its Range Rapidly

Silicone oil production lines, equipped with advanced devices like reaction stills and water - ring roots vacuum pump units, are employed to manufacture high - quality silicone oil. The production process, from raw material preparation to packaging, is strictly controlled. Silicone oil is extensively used in multiple industries, including cosmetics for its smooth - feeling properties, in electronics for heat dissipation and insulation, and in the automotive industry for lubrication. Lately, with the continuous development of technology, the application scope of silicone oil is expanding rapidly, showing great market potential and application value.

Production Process

- Raw Material Preparation:The main raw material of silicone oil is dimethylsiloxane (D4), a colorless and transparent liquid. Before production, it is necessary to ensure that sufficient D4 raw materials are prepared and strictly test their quality to ensure that the purity and performance of the raw materials meet the production requirements, laying a good foundation for subsequent synthesis reactions.

- Synthesis Reaction):During the production process, D4 enters the reactor with stabilizers, catalysts and other auxiliaries for mixing. Then, under certain temperature and pressure conditions, D4 is converted into silicone oil through polymerization reaction. This process requires precise control of reaction parameters to ensure the smooth progress of the reaction and the quality of the product, ensuring that the produced silicone oil has good performance and stability.

- Separation and Purification):After the synthesis reaction, there may still be some unreacted impurities in the silicone oil produced, such as catalyst residues, stabilizers, etc. In order to obtain pure silicone oil products, a separation and purification process is required. Distillation, filtration, crystallization and other methods are usually used to remove impurities and improve the purity of silicone oil to meet the quality requirements of different application fields.

- Adjust Product Performance):According to different application fields and needs, the performance of silicone oil needs to be adjusted. For example, by adding different additives, the viscosity, fluidity, oxidation resistance and other properties of silicone oil can be changed, making it better meet the usage requirements of various industrial and daily - life scenarios and broadening the application scope of silicone oil.

- Packaging and Storage):After the above steps, the production process of silicone oil is basically completed. Finally, silicone oil needs to be packaged and stored to ensure its quality and stability. It is usually packaged in iron drums, plastic drums and other containers and stored in a cool, dry place away from direct sunlight and high temperature environments to prevent silicone oil from deteriorating or its performance from declining due to environmental factors.

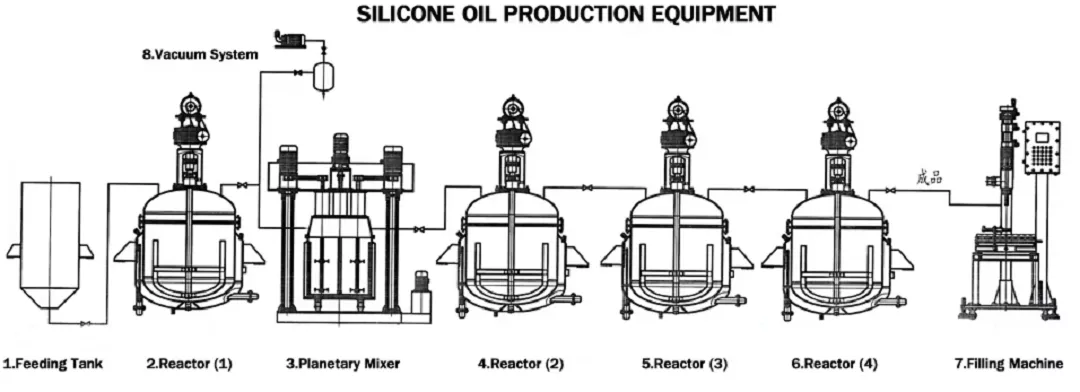

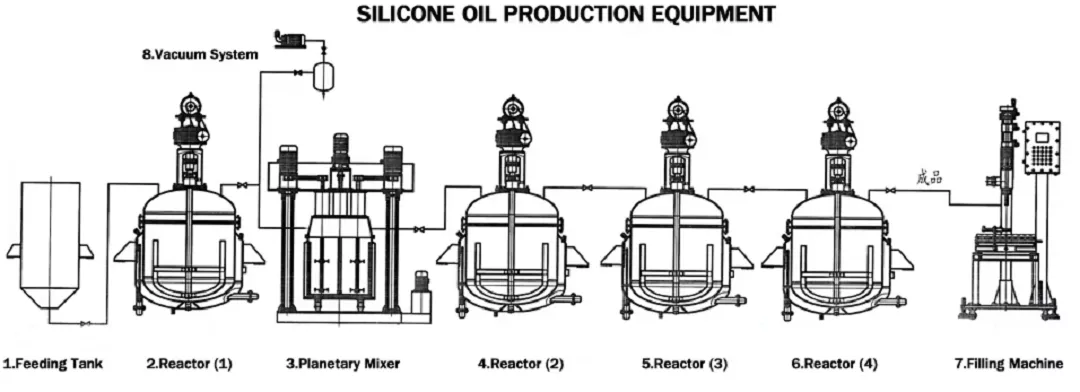

Production Line Equipment Configuration

- Reaction still:The reaction still is the core equipment for the synthesis reaction of silicone oil, providing a stable space and conditions for the reaction. It can accurately control parameters such as temperature and pressure required for the reaction, ensuring that dimethylsiloxane (D4) is fully mixed with stabilizers, catalysts and other auxiliaries in a suitable environment and undergoes a polymerization reaction, thus efficiently producing silicone oil.

- Water ring - roots vacuum pump unit:The water ring - roots vacuum pump unit can effectively extract non - condensable gases and water vapor from the reaction system during the reaction, maintaining the vacuum degree of the reaction environment. This not only helps to improve the reaction rate and product purity, but also prevents product quality problems caused by gas residues, ensuring the smooth progress of the silicone oil production process.

- Automatic metering storage tank:The automatic metering storage tank can accurately measure the amount of various raw materials, ensuring the accuracy and stability of raw material addition during the production process. At the same time, it also has a storage function and can pre - store a certain amount of raw materials before production, providing a guarantee for continuous production and avoiding production interruption due to insufficient raw material supply.

- Material cooling system:After the silicone oil synthesis reaction is completed, the material cooling system can quickly cool the reaction products to an appropriate temperature, preventing changes in the performance of silicone oil due to high temperature. By precisely controlling the cooling rate and temperature, the quality and stability of silicone oil are ensured, preparing for subsequent processes such as separation and purification.

- Semi - automatic filtering filler:In the final stage of silicone oil production, the semi - automatic filtering filler plays an important role. It can filter the silicone oil after separation, purification and performance adjustment, removing possible remaining tiny impurities and further improving product quality. At the same time, it also has a semi - automatic filling function and can accurately fill silicone oil into containers such as iron drums and plastic drums according to different packaging specifications, improving packaging efficiency and product sealing.

Application Fields

- Aerospace Field: [Insert relevant application pictures, such as aircraft component seals] In the demanding environment of aerospace, HTV silicone rubber, relying on its high-temperature resistance, aging resistance, and other properties, provides reliable sealing and insulation for critical parts of aircraft, contributing to flight safety and performance stability.

- Automotive Industry: [Insert pictures of automotive engine peripheral seals and other applications] Applied to parts such as the engine and electronic systems of automobiles for sealing and protection, it effectively resists the influence of oil fluid erosion and temperature changes, prolongs the service life of automotive parts, and improves overall performance.

- Construction Industry: [Insert pictures of building exterior sealant strips and other applications] As a building exterior sealing material, depending on its weather resistance and UV resistance properties, it maintains good sealing performance for a long time, prevents rainwater and air infiltration, and maintains the stability of the building structure.

ABOUT JCT

JCT Machinery was founded in 2006. Its business involves mechanical equipment design and manufacturing, intelligent control system research and development, engineering design and installation, etc. The main products include resin synthesis reaction production line, adhesive manufacturing production line, etc., which are widely used. They mainly serve and are used in the fields of fine chemicals, coatings, adhesives, and other fields.

JCT's equipment and production lines have many Patents and areCE-certified. Its customers are spread over more than 30 countries and regions around the world and have been widely recognized and supported by many large and small companies at home and abroad.

JCT has an independent office and factory in Foshan, Guangdong, less than 1 hour's drive from Guangzhou Baiyun International Airport and Guangzhou South High-speed Railway Station. Customers are welcome to come for a face-to-face interview. JCT's sales and engineers will be very willing to have detailed technical communication and discuss optimization technical solutions with you.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a factory.

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can helo you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technicalparameters for you and send you the detailed drawings. Once you confirm without questions, we will put it into production.