Nail free glue is a high-strength, quick drying adhesive for construction and home furnishing, widely used in the fixing and installation of various substrates such as wood, metal, ceramics, stone, plastic, etc. With the development of prefabricated construction and home decoration industries, the market demand for nail free glue continues to grow.

1. Raw material storage tank

Store raw materials such as base resin, thickener, filler, additives, etc.

Equipped with heating and stirring functions to maintain material fluidity.

2. Automatic metering and batching system

Accurately measure various raw materials and automatically add materials according to the formula.

Improve production efficiency, ensure accurate ratio and stable product quality.

3. Powerful dispersing mixer

Quickly disperse powder and liquid raw materials to form a uniform mixture.

Break agglomerates, improve filler dispersion, and enhance the delicate feeling of colloid.

4. Double planetary mixer

Suitable for high viscosity and heavy load mixing.

Adopt planetary stirring, mixing without dead corners, stirring evenly and thoroughly, especially suitable for high viscosity materials such as nail free glue.

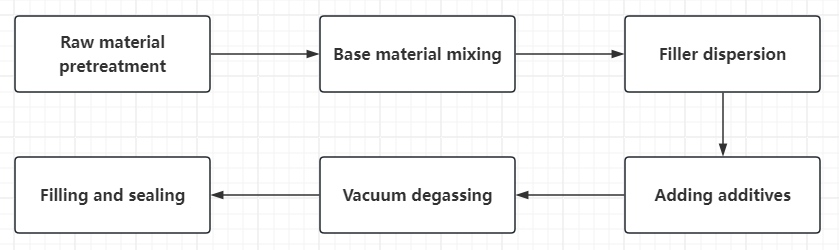

5. Vacuum degassing system

Vacuum degassing is performed simultaneously during the mixing process.

Effectively remove bubbles and improve the density and bonding strength of nail free glue.

6. Heating system

Can be jacket heating or external circulation heating.

Control the temperature of the material during the production process to ensure viscosity and fluidity.

7. High viscosity discharge pump

Use a special high viscosity gear pump or screw pump to smoothly transport the finished rubber to the packaging process.

8. Filling machine

Quantitatively fill nail free glue into various packaging containers, such as plastic bottles, soft packaging bags, glue gun barrels, etc.

Supports semi-automatic or fully automatic filling.

| Problem | Possible Cause | Solution |

| Slow curing | Low humidity / excessive solvent | Add moisture catalyst |

| Bubbles | Incomplete degassing / water content in filler | Extend vacuum degassing time + dry raw materials |

| Layered sedimentation | Insufficient filler fineness / failure of thixotropic agent | Optimize grinding process + add fumed silica |

| Difficult extrusion | Too high viscosity / unmatched hose diameter | Adjust solvent ratio + replace large-diameter filling head |