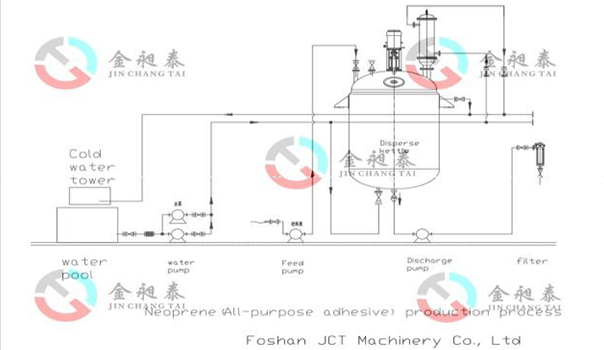

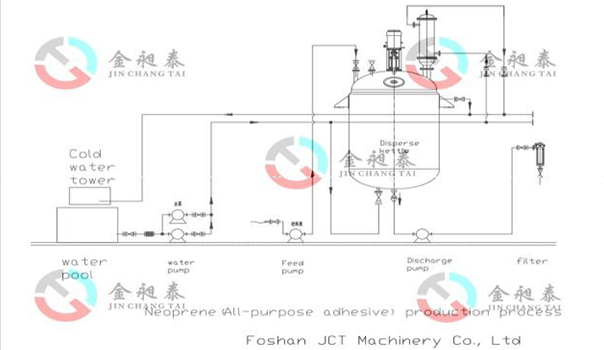

Neoprene Glue Production Line Equipment Configuration

- Reactor

- Condenser

- Dispersing kettle

- Filter

- Filling machine

- Steam furnace

- Water cooling system

- Material pump

- Raw material tank

- Finished storage tank

- Metering tank

Neoprene Glue Production Process

- All kinds of raw materials are prepared according to the technical formula.

- The solvent, resin and metal oxide are added to the reactor for about 2 hours mixing.

- According to the formula requirements to joint EAC. Different kinds of neoprene rubber, resin, antioxidant, etc.

- The mixture is homogeneous and completely dissolved.

- Sampling inspection, qualified after packing.

Neoprene Glue Production Line Specifications

- 500L-1500L Neoprene glue production line

- 2000L-3000L Neoprene glue production line

- 4000L-6000L Neoprene glue production line

- 8000L-12000L Neoprene glue production line

It can be designed according to the actual needs.