Widely Applied and Expanding its Range Rapidly

Liquid silicone rubber is a material with excellent properties, which is widely used in various fields due to its key characteristics.

Product Features

- Quick hardening and low compression ratio: It can harden in a short time and shows a low compression ratio under pressure, ensuring stability during use.

- Strong tolerance: - Tear resistance: It has excellent tear - resistance and can withstand certain external forces without being easily damaged.

- High - temperature resistance: It can be used in high - temperature environments and has a wide temperature tolerance range to meet the needs of different high - temperature working conditions.

- Water and oil resistance: When facing media such as water and oil, it can still maintain good performance without being eroded. -

- Special physical properties: It has a certain degree of transparency and good electrical conductivity, which can be applied to specific application scenarios with requirements for these properties.

- High strength and long life: It has reliable overall strength and long service life, can work stably for a long time, reduce the replacement frequency, and save costs.

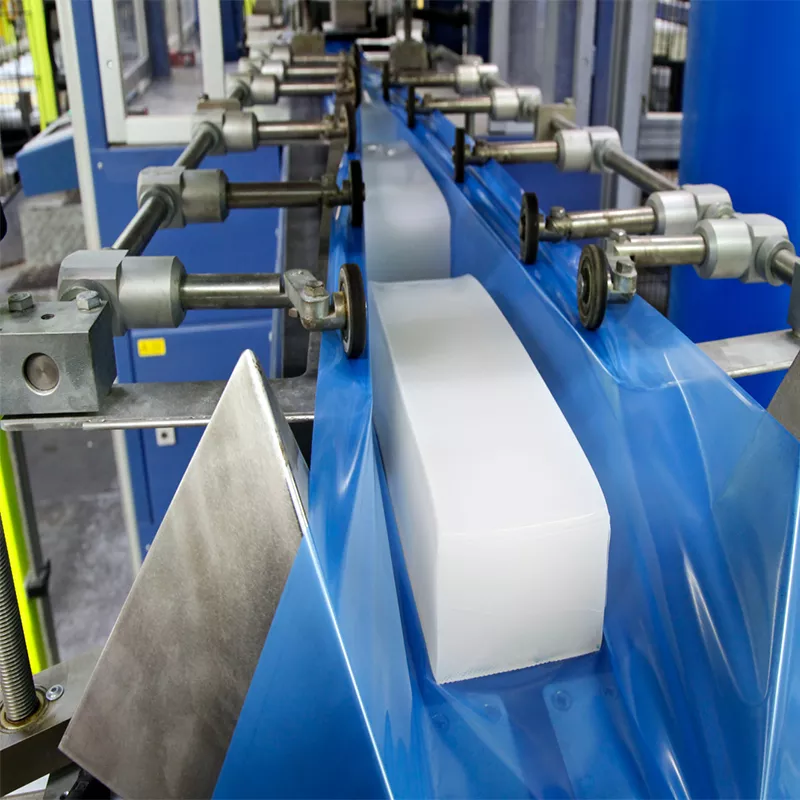

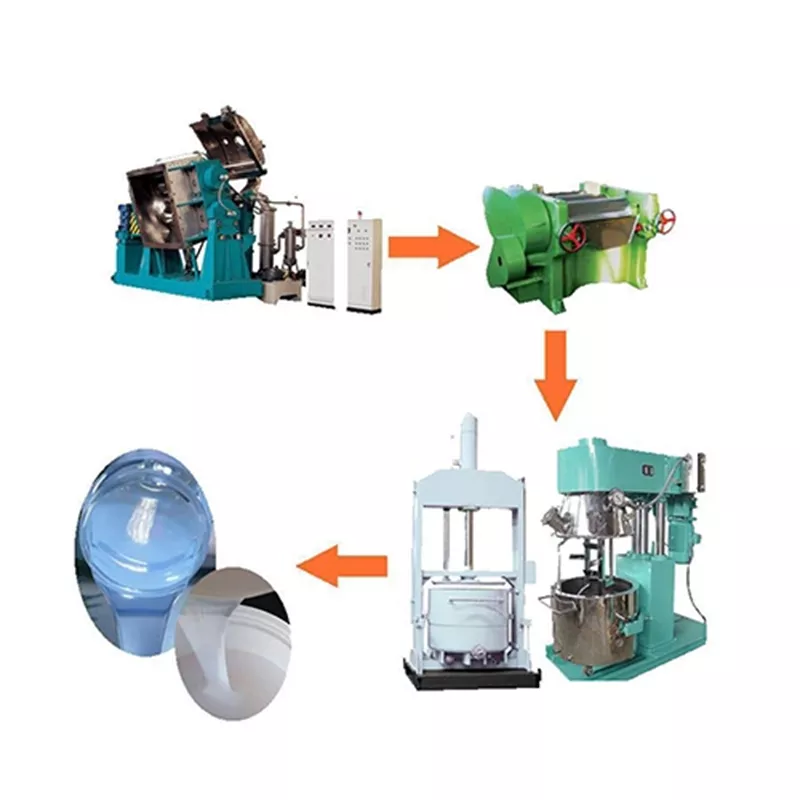

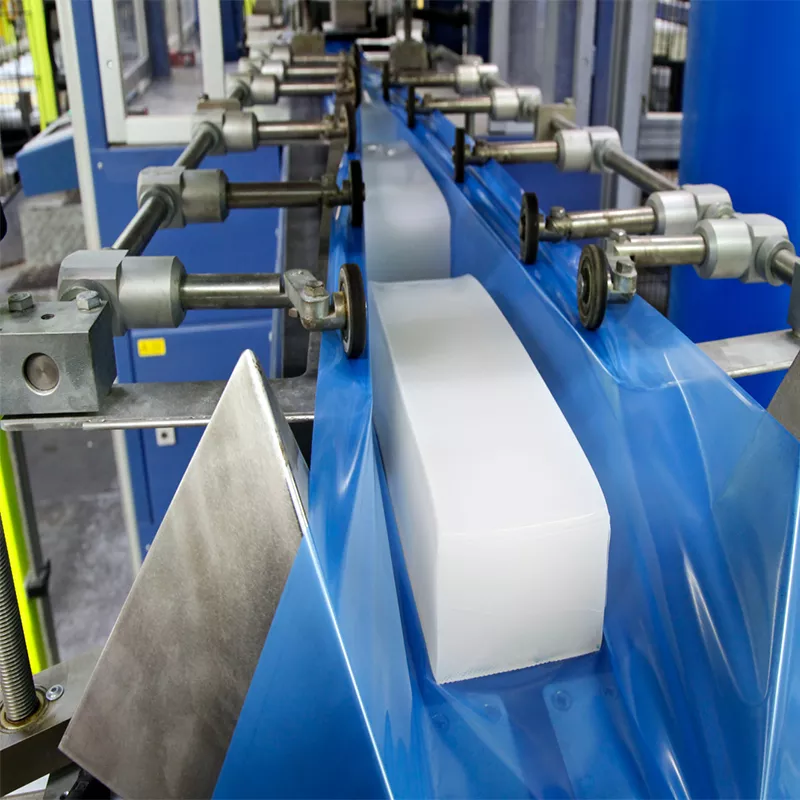

Production Line Equipment Configuration

- Vacuum kneader: Plays a key role in the initial stage of production, used for mixing raw materials and removing water from the materials through the vacuum system, laying a good foundation for subsequent processes.

- High - viscosity pump: Responsible for transporting the produced base material to the base - material storage tank, ensuring the stable transfer of materials and the smooth connection of the production process.

- Base - material storage tank: Used to store the base material, providing a reserve for accurately adding materials to subsequent processing equipment.

- Heating system: Can heat the materials in a timely manner according to the production process requirements, meeting the temperature needs at different stages and facilitating the full reaction and processing of the materials.

- Vacuum system: Enabled in multiple production links, it can not only effectively remove the water in the materials but also extract air, avoiding factors such as air bubbles in the materials that affect product quality.

- Three - roll grinding machine: Fine - grinds the base material to make it meet the specified fineness requirements, ensuring that the product has a fine and uniform texture and meets high - quality standards.

- Multi - function dispersing and mixing machine or planetary mixer: Plays a core role in the material mixing process. Through high - speed stirring and dispersing operations, all components are fully and evenly mixed. At the same time, it cooperates with the vacuum system and cooling system to further optimize the material state.

- Hydraulic discharging machine: After the production is completed, it unloads the mixed materials from the mixing cylinder and divides them into packaging drums, facilitating the subsequent packaging and storage links.

- Cooling system: Started in a timely manner during the production process, it precisely controls the temperature of the materials, avoiding the adverse effects of excessive temperature on product performance and ensuring that the entire production process is in a suitable temperature environment.

Application Areas

Due to the excellent properties of liquid silicone rubber and the guarantee of strict production processes, it is suitable for many industries such as [list some common application fields, such as electronic appliances, automotive manufacturing, medical devices, etc.], and can meet the strict requirements for material performance in different scenarios.

Quality Assurance

Throughout the entire production process, we strictly control every link, from the selection of raw materials, the precise operation of production equipment to the strict implementation of the production process, all follow high - standard quality control systems to ensure that each batch of liquid silicone rubber products can achieve stable and excellent quality, providing reliable product support for customers.

ABOUT JCT

JCT Machinery was founded in 2006. Its business involves mechanical equipment design and manufacturing, intelligent control system research and development, engineering design and installation, etc. The main products include resin synthesis reaction production line, adhesive manufacturing production line, etc., which are widely used. They mainly serve and are used in the fields of fine chemicals, coatings, adhesives, and other fields.

JCT's equipment and production lines have many Patents and areCE-certified. Its customers are spread over more than 30 countries and regions around the world and have been widely recognized and supported by many large and small companies at home and abroad.

JCT has an independent office and factory in Foshan, Guangdong, less than 1 hour's drive from Guangzhou Baiyun International Airport and Guangzhou South High-speed Railway Station. Customers are welcome to come for a face-to-face interview. JCT's sales and engineers will be very willing to have detailed technical communication and discuss optimization technical solutions with you.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a factory.

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can helo you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technicalparameters for you and send you the detailed drawings. Once you confirm without questions, we will put it into production.